Nature often offers promising inspiration for biomimetic man-made materials. In a new report now published in Advanced Science, Faheng Wang and a team of scientists in advanced materials, engineering and science in China developed new cement materials based on unidirectionally porous architectures to replicate the designs of natural wood. The resulting wood-like cement material showed higher strength at equal densities, alongside multifunctional properties for effective thermal insulation, water permeability and easy adjustment for water repulsion. The team simultaneously achieved high strength and multifunctionality to make the wood-like cement a promising new building material for wood-mimetic designs with high performance. They presented a simple fabrication procedure to promote better efficiency during mass production with applications suited across other material systems.

Developing bioinspired wood-like materials

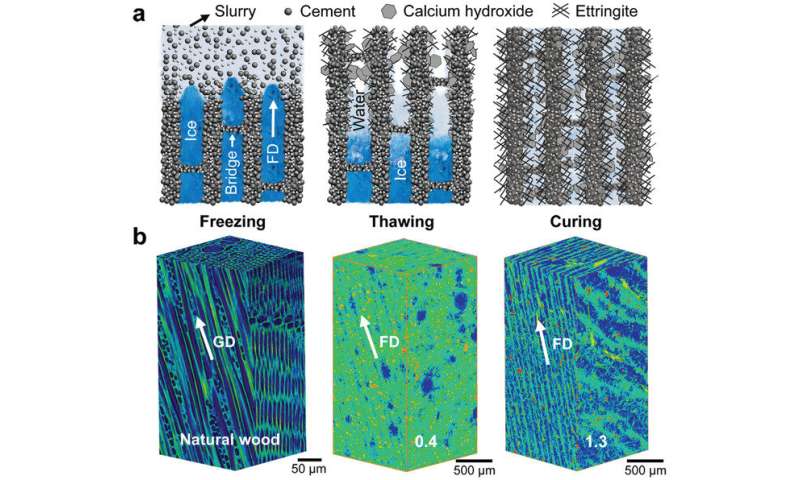

Porous cement-based materials possess low thermal conductivity for heat insulation, high sound-absorbing efficiency, outstanding permeability for air and water, while maintaining light weight and fire resistance. However, it still remains a key challenge to achieve the simultaneous enhancement of both mechanical and multifunctional properties including mechanical support, effective transport and good thermal insulation. It is therefore highly desirable to generate materials with enhanced mechanical and multifunctional properties to actively implement the design principles of natural wood. During the experiments, Wang et al. developed wood-like cement with unidirectionally porous architectures formed via a bidirectional freezing treatment method. The process allowed bridges to form between the constituents of the structure, the team then thawed the fully frozen bodies until the ice gradually melted and the cement hardened. The subsequent hydration process produced new minerals and gels within the cement, including hexagon-shaped calcium hydroxide, needle‐like ettringite and calcium-silicate-hydrate gels. The phases mainly originated at the cement lamellae and grew into their spacing during the thawing and curing process for better structural integrity with enhanced lamellae interconnections during porous cement formation. Using X-ray tomography (XRT), the team then revealed the formation of unidirectional micropores in the ice-templated cement.

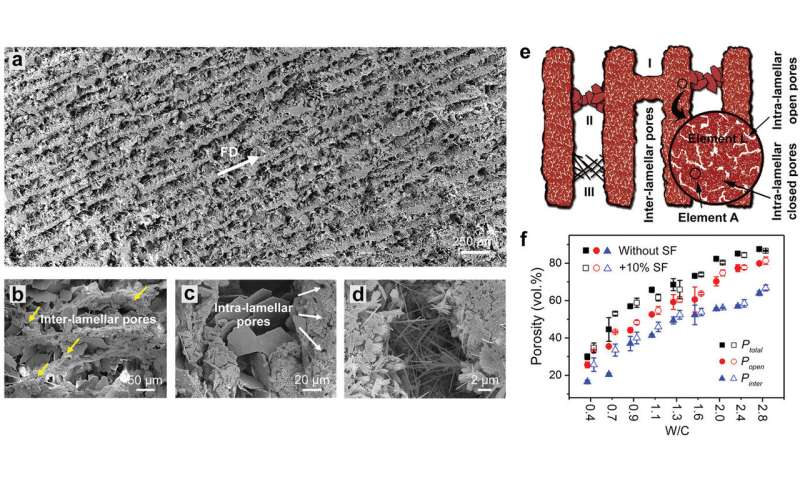

Wang et al. used scanning electron microscopy (SEM) images to reveal the unidirectional pores between lamellae in the ice-templated cement that encompassed a large amount of interconnections bridging the lamellae. The team classified the interconnections into three types: (1) bridges and intersections formed due to cement particles engulfed in ice crystals during the process of freezing, (2) hexagon-shaped calcium hydroxide, and (3) needle-like ettringite. The latter minerals resulted from hydration reactions of cement during the thawing and curing processes. The cement lamellae contained abundant pores formed during the cement drying process due to the dehydration of gels and the removal of water. The scientists classified the pores within wood-like cement into three types, including (1) interlamellar open pores, (2) intralamellar open pores and (3) intralamellar closed pores. The interlamellar porosity was principally governed by the water content, which played a role as a pore-forming agent.

-

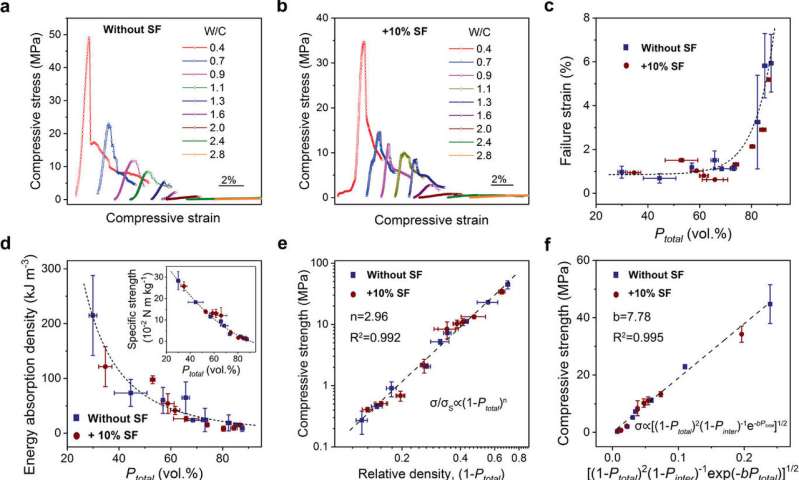

Mechanical properties of wood‐like cement. a,b) Representative compressive stress–strain curves of the wood‐like cement made from slurries with differing W/C a) without and b) with SF additions. c,d) Variations in the c) failure strain, d) energy absorption density, represented using the area under stress–strain curve until the peak stress, and specific strength (inset in panel (d)) as a function of the total porosity Ptotal. The general varying trends are indicated by the dashed curves for clarity. e) Dependence of the compressive strength on the relative density in the wood‐like cement. f) Interpretation of the strength according to the equivalent element approach by taking different types of pores into account. The data in panels (c)–(f) are obtained from at least three measurements for each set of samples and presented in form of mean ± standard deviation. Credit: Advanced Science, doi: 10.1002/advs.202000096 -

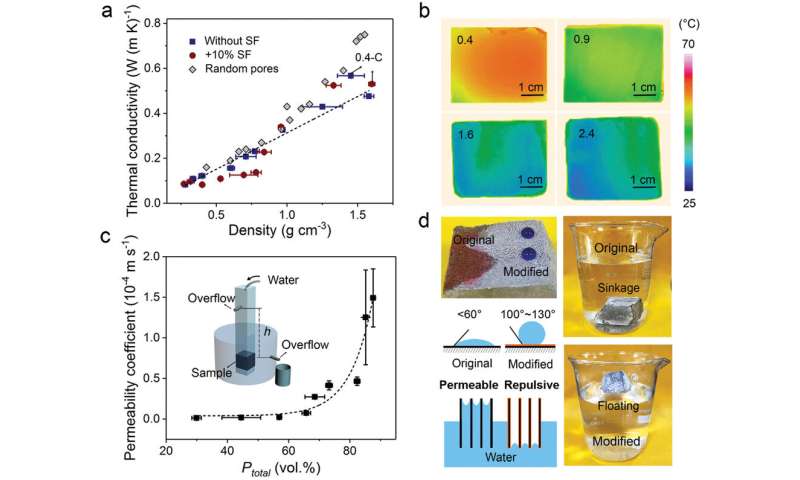

Multifunctional characteristics of wood‐like cement. a) Variations in the thermal conductivity coefficient of wood‐like cement at the transverse profile as a function of nominal density. 0.4‐C indicates the cement made from slurries with a W/C of 0.4 but without ice‐templating treatment. The data for randomly open‐celled porous cement materials are also shown for comparison.[35, 36] b) Infrared images of cement made from slurries with differing W/C values of 0.4, 0.9, 1.6, and 2.4 placed on a heating plate of 100 °C. c) Dependence of the water permeability coefficient along the vertical direction on the total porosity Ptotal in wood‐like cement. The setup used for water permeability measurement is illustrated in the inset. d) Images and schematic illustrations showing the water permeable and repulsive nature of the cement before and after waterproofing treatment, along with the capillary attraction and repulsion effects of internal surfaces owing to the hydrophilic and hydrophobic characteristics. The data in panels (a) and (c) are obtained from at least three measurements for each set of samples and presented in form of mean ± standard deviation. The general varying trends are indicated by dashed curves for clarity. Credit: Advanced Science, doi: 10.1002/advs.202000096

The mechanical and multifunctional properties of the material

The team obtained representative compressive stress-strain curves of the wood-like cement with or without silicon fume additions to its constitution. The compressive strength decreased monotonically with the rising water/cement ratios in the slurries used to develop the material, which eventually led to increased porosity in the cement. Since the failure strain of the material increased with increased total porosity, the strength of porous solids could be determined by its porosity. The team next measured the thermal conductivity coefficient of ice-templated, wood-like cement to show decreasing thermal conductivity with increasing porosity of the material. They also used infrared (IR) images to clearly observe the robust thermal insulation properties of the ice-templated cement material. To regulate the thermal insulation efficiency, Wang et al. adjusted the solid load in the cementitious slurries by increasing the water/cement content. The resulting cement material absorbed water due to the hydrophilic (water attractive) character of its internal surfaces. In contrast, they could prevent water penetrating the pores by waterproofing the surfaces with an organosilicon agent; such efforts on hydrophobicity could even cause the material to float on water. The method can therefore facilitate switchable applications as pervious or waterproof structures suited as building-materials.

![Comparison of wood‐like cement with natural wood and other porous cement materials.[3-8, 31, 43, 53, 59-61] a) Compressive strength and density for a wide range of porous cement‐based materials showing the relatively higher strengths of current wood‐like cement at equal densities. LAC: lightweight aggregate content; OPC: ordinary Portland cement; PF: polypropylene fiber; PC: Portland cement; CSA: concrete sludge aggregate; S/C: sand‐to‐cement ratio in weight. b) Schematic illustrations about the design strategies of natural wood and wood‐like cement in optimizing their mechanical and multifunctional properties associated with the unidirectionally porous architectures. The strength and density data of current wood‐like cement in panel (a) are presented in form of mean ± standard deviation. Credit: Advanced Science, doi: 10.1002/advs.202000096 Wood-inspired cement with high strength and multifunctionality](https://scx1.b-cdn.net/csz/news/800/2021/4-woodinspired.jpg)

Outlook for wood-like cement materials

In this way, Faheng Wang and colleagues presented an ice-templating technique as a viable approach to create unidirectional micropores for applications across ceramics, polymers, metals and their composites. The scientists developed a freeze-drying treatment process based on the self-hardening behavior of cement when in contact with hydration reactions. The resulting wood-like cement architecture contained a variety of pores in either open or closed forms and an abundance of interconnections bridging their lamellae. When the porosity increased, the strength of the cement decreased. The wood-like cement also featured lower thermal conductivity and good water permeability. The team could switch the cement material to be either water-repulsive or water-attractive via hydrophobic or hydrophilic treatment, respectively. The simple and practical materials development strategy coupled to the self-hardening nature of its constituents can significantly improve the time- and cost-effectiveness of the ice-templating technique to form sustainable concrete with potential to translate the method across to other material systems.

Explore further

Monteiro P. et al. Towards sustainable concrete, Nature Materials, doi.org/10.1038/nmat4930

Roy D. M. New Strong Cement Materials: Chemically Bonded Ceramics, Science, 10.1126/science.235.4789.651

© 2021 Science X Network

Citation: Wood-inspired cement with high strength and multifunctionality (2021, January 5) retrieved 5 January 2021 from https://ift.tt/38eA8dX

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

"wood" - Google News

January 05, 2021 at 09:30PM

https://ift.tt/38eA8dX

Wood-inspired cement with high strength and multifunctionality - Phys.org

"wood" - Google News

https://ift.tt/3du6D7I

No comments:

Post a Comment